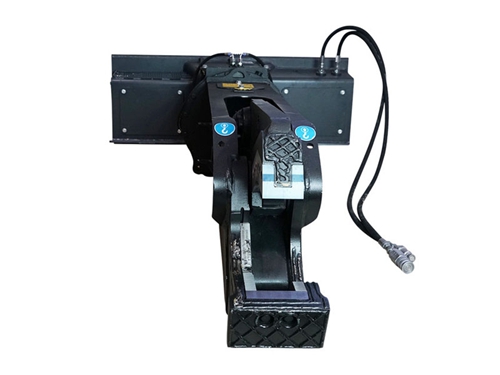

In metal recycling, demolition, and industrial dismantling applications, efficiency, safety, and operational flexibility are critical. The Skid Steer Scrap Shears equipped with a rugged 360° rotation system are engineered to meet these demands, delivering reliable cutting performance in demanding jobsite conditions.

Full 360° Rotation for Maximum Control

The integrated 360-degree continuous rotation system allows operators to accurately position the cutting jaws without repositioning the skid steer loader. This feature significantly improves productivity, especially in confined or complex working environments.

Straight Lower Jaw Design for Enhanced Cutting Efficiency

Unlike conventional scrap shears that concentrate force at the jaw tip, this model features a straight lower jaw design. Material is distributed evenly along the jaw length, resulting in improved cutting efficiency, reduced stress on components, and longer service life.

Balanced Size and Robust Construction

Designed for optimal compatibility with skid steer loaders, the shear offers a practical balance between cutting power and overall weight.

Key specifications include:

- Width: 1610 mm

- Rotation Angle: 360°

- Maximum Opening: 275 mm

- Weight: Approximately 320 kg

Typical Applications

This attachment is well suited for:

- Scrap metal processing and recycling

- Structural steel and building demolition

- Industrial equipment dismantling

- Material handling and sorting in recycling facilities

Its rotational capability makes it particularly effective in applications requiring precise positioning and continuous operation.

Conclusion

The 360° rotating skid steer scrap shear is a dependable attachment for professionals seeking increased productivity and operational flexibility. With its durable construction and well-engineered cutting geometry, it represents a practical investment for demolition contractors, recycling operators, and equipment rental businesses.